Maintaining electrical systems and machinery

Make infrared thermography part of your preventive maintenance.

If not detected and corrected early, excessive heat due to problems with electrical or mechanical systems can lead to equipment failures, lengthy production shut-downs and catastrophic fires.

More than two-thirds of electrical system failures can be prevented by having a routine preventive maintenance program. In fact, the failure rate of electrical equipment is three times higher for components that aren’t part of a scheduled preventive maintenance program.

Infrared thermography is the practice of using specialized electronic cameras to identify heat patterns and, in special situations, to measure temperatures. The most typical type of thermography cameras produce live and still images of heat radiation, called thermograms or thermographs. Thermal imaging cameras can detect very minor temperature differentials that can be useful in analyzing potential problem areas in your electrical production equipment.

Benefits of thermographic surveys

- Early detection of problem areas, allowing sufficient time to acquire replacement parts or perform necessary maintenance

- More accurate estimates of equipment life span

- Reduction or prevention of emergency maintenance

- Improved overall productivity and profitability

In order for thermal imaging to be effective, equipment under evaluation should be operating at a minimum of 40% of rated load and should be in operation for a sufficient time period to allow operational temperatures to stabilize (steady-state). Thermal imaging cameras must “see” the item to be evaluated for temperature differences. This requires a direct line of sight to the equipment to be evaluated. Electrical panels need to be opened and their cover plates removed to expose components and wiring.

Because electrical panels must be accessed when energized and under load, a trained electrician is needed to safely access electrical equipment so images can be taken. The electrician is required to wear clothing that protects against the exposure to arc flash, as identified in National Fire Protection Association Standard, 70E, Standard for Electrical Safety in the Workplace.

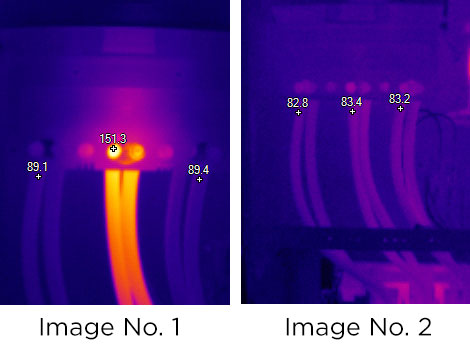

Sample images from thermographic cameras

Image No. 1 shows the three phases of a 480-volt service to a motor on a key piece of production equipment. Shutdown of the equipment would have imposed an almost complete loss of production (and loss of income) until repairs could be made. The center phase of the service was identified to have a high-resistance connection, which resulted in this phase being considerably warmer than the adjacent electrical phases. Image No. 2 shows the three phases of a 480-volt service to the motor after the wiring was removed and properly reconnected.

Who should consider thermographic surveys?

- Businesses with very limited operational seasons that cannot tolerate even minimal downtime

- Businesses with continuous multiple shifts, which do not permit extended maintenance periods

- Operations with critical equipment that could pose a severe bottleneck to production, or which have a substantial replacement lead time

- Businesses with extensive preventive maintenance budgets that want to reduce maintenance costs

Nationwide maintains a staff of trained Level 1 certified thermographers available to conduct site surveys of your facility.

Our thermographers are equipped with thermal imaging cameras and all the necessary arc flash personal protective equipment required to safely conduct surveys of electrical services up to 600 volts. Upon completion of the site survey, a report is provided that includes thermal images of any potential problem areas and recommendations for corrective actions.

There is no additional cost to the client for these services, but clients will be expected to provide a trained electrician who is properly outfitted with arc flash clothing to open and close electrical panels for the duration of site surveys.

To learn more or to request a thermal imaging survey, contact your agribusiness risk management consultant at Nationwide by calling 1-800-260-1356 or emailing rmdesk@nationwide.com.

>

>

>

>

>

>